Our products have multiple packaging options and provide design support.

-

Cable tie packaging

-

Outer box packaging

MATERIAL: Polyamide 6.6

Material brand: Huafon626F; Invista 4820L

Flammability of raw material : UL 94 - V2

Humidity absorption: 2,7%-2,8% (23°C -50% R.H.)

Installation temperature: -10°C ~+85°C.

Working temperature:-40°C ~+85°C.

Max sustaiaable tempeature for short time:+110°C.

W9.0mm Type

PERFECT FOR WIRE BUNDLING APPLICATIONS

Extra Heavy Duty Cable Ties (also called wire ties, large zip ties or tie wraps) are effective in applications requiring up to 79KG(175 lb) tensile strengths. The one piece construction allows for consistent performance and reliability. For heavier duty cable and wire bundling applications, a 79KG(175 lb) cable tie is recommended and is available in lengths from 380mm--1530mm(158”--60”). Natural ties are preferred for indoor use applications while UV Black is recommended for outdoor applications, providing greater resistance to ultraviolet light. Cable Tie Express stocks the 79KG(175 lb)cable ties in standard packages of 100 or 50 depending upon the weight and length of the cable tie.

Standard self - locking cable ties come in various specifications, including 2.5mm mini ties, 3.6mm medium ties, 4.8mm standard ties, 7.6mm heavy - duty ties, 9mm extra - heavy - duty ties, and 12.4mm ultra - extra - heavy - duty ties. These ties are made from high - strength nylon66 material, providing excellent durability and tensile strength, making them suitable for various industrial and everyday applications. The self - locking design ensures reliable fastening, easy installation, and removal, making them ideal for cable bundling, cable management, and other fastening needs. The different specifications offer flexibility to meet diverse requirements ranging from light to heavy bundling, widely used in electronics, automotive, home decoration, and industrial manufacturing.

cable ties are available in both bulk 1,000 pieces bags and smaller 100 pieces bags. A full range of standard and fluorescent colors of the Miniature ties are available.

⌾Excellent 〇 Good △Medium

| Product Name | FSCAT Cable Ties | ||||

| Type | TST | FST | FS | FS | FS |

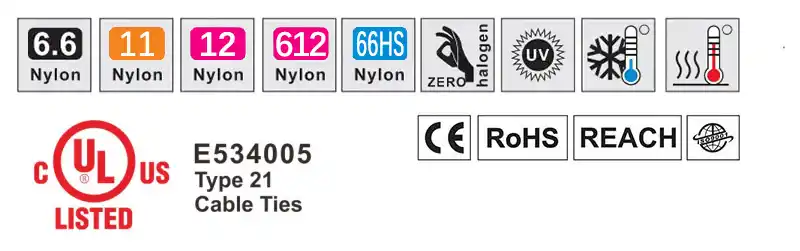

| Material | Polyamide 6.6 | Polyamide 6.6 | Polyamide 612 | Polyamide 12 | Polyamide 6.6HS |

| Operating Temperature | |||||

| Max. | 85℃(185℉) | 85℃(185℉) | 85℃(185℉) | 85℃(185℉) | 110℃(230℉) |

| Min. | -40℃(-40℉) | -40℃(-40℉) | -40℃(-40℉) | -40℃(-40℉) | -40℃(-40℉) |

| UV light/ozone | △ | △ | ⌾ | ⌾ | 〇 |

| Oils and greases | ⌾ | ⌾ | ⌾ | ⌾ | ⌾ |

| Solvents | 〇 | 〇 | 〇 | 〇 | ⌾ |

| Petrol | ⌾ | ⌾ | ⌾ | ⌾ | ⌾ |

| Flammability | UL94V-2 | UL94V-2 | UL94VHB | UL94VHB | UL94HB |

| Item No. | Width | Length | Max.Bundle Dia. | Min.Tensile Strength | Package | Material | ||

| mm/inch | mm/inch | mm/inch | N | kg | lbs | Pcs/Bag | ||

| TST-175EHD | 9.0(0.354) | 175(6.89) | 40(1.57) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-200EHD | 9.0(0.354) | 200(7.88) | 50(1.97) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-300EHD | 9.0(0.354) | 300(11.82) | 80(3.15) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-380EHD | 9.0(0.354) | 380(14.96) | 102(4.02) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-400EHD | 9.0(0.354) | 400(15.75) | 105(4.13) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-430EHD | 9.0(0.354) | 430(16.93) | 110(4.33) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-450EHD | 9.0(0.354) | 450(17.72) | 118(4.65) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-500EHD | 9.0(0.354) | 500(19.69) | 150(5.91) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-530EHD | 9.0(0.354) | 530(20.87) | 155(6.10) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-550EHD | 9.0(0.354) | 550(21.65) | 160(6.30) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-650EHD | 9.0(0.354) | 650(25.59) | 185(7.28) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-710EHD | 9.0(0.354) | 710(27.95) | 195(7.68) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-760EHD | 9.0(0.354) | 760(29.92) | 205(8.07) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-820EHD | 9.0(0.354) | 820(32.28) | 235(9.25) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-920EHD | 9.0(0.354) | 920(36.22) | 280(11.02) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-1020EHD | 9.0(0.354) | 1020(40.16) | 295(11.61) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-1168EHD | 9.0(0.354) | 1168(45.98) | 340(13.39) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-1220EHD | 9.0(0.354) | 1220(48.03) | 375(14.76) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-1350EHD | 9.0(0.354) | 1350(53.15) | 400(15.75) | 778 | 79.4 | 175 | 100 | PA66 |

| TST-1530EHD | 9.0(0.354) | 1530(60.24) | 450(17.72) | 778 | 79.4 | 175 | 100 | PA66 |

TST-450GHD TST-450GHD |

7.6(0.299) | 450(17.72) | 130(5.12) | 560 | 57.1 | 130 | 100 | PA66 |

TST-500GHD TST-500GHD |

7.6(0.299) | 500(19.69) | 150(5.91) | 560 | 57.1 | 130 | 100 | PA66 |

Quantity customization:  100/250/500/1000pcs/ba

100/250/500/1000pcs/ba  100/250/500 pcs/bags

100/250/500 pcs/bags  100/250 pcs/bags

100/250 pcs/bags

Our products have multiple packaging options and provide design support.

Cable tie packaging

Outer box packaging

This technology is used in 90% of all polyamide (PA)cable ties applied by Tolerance. in order to cover a varietyof applications, thereare diferent variants of this system, for example: releasable verslons and in-line versions, These are one-piece cable ties, that thepawl is moulded as an integral part of the cable tie, thereby building in inherent strenaths.

Locking technologyPositive locking is achieved by engaging the pawl with the strap serrations. This allows the cable tie to perform to the publishedminimum tensile strength, that is the load that the cable tie can hold under application,

Made of stainless steel grades 304 or 316, the MlG range of cable ties has no serations on the strap and are threaded parallel throughthe head, glding undera metal bal-bearing locking mechanism.By using the GlT-705 appication toolthe cable tie is tensioned andthe strap cut to a flush finish.

Locking technologyThe strap is locked into the head by means of the smalbal-bearing.The ball locks into the smal end of thewedged shapedhousing, forming a positive locking with the strap.

The minimum tensile strength is a critical selection criterion for cable ties. it expresses how much loada cable tie can bear. This minimum tensile strenath is determined in accordance with the MilitarySpecificationand Standards of the UsA. Test conditions are precisely defined in MlL-S-23190E

The cable tie is fixed onto a split mandrel test probe with the suitable cable tie application tool

A: Absolutely. We specialize in OEM/ODM solutions for global retail chains. We offer.

1.Custom Packaging: Polybags with Euro-Holes (for hanging), Cylinder Tubes, or Blister Packs.

2.Private Labeling: We can print your Logo, Brand Design, and UPC/EAN Barcodes directly on the header card or sticker, ensuring products are "Shelf-Ready" upon arrival.

3.Laser Marking: We also support laser logo engraving directly on the cable tie tail for brand anti-counterfeiting.

A: As a manufacturer supplying industry leaders like Panduit and HellermannTyton, our daily output exceeds 5 Tons

1.For Stock Items: Dispatched within 3-5 days.

2.For OEM/Container Orders: Standard lead time is 15-20 days after deposit. We guarantee stable delivery schedules to prevent stock-outs in your distribution channel.

A: Quality is our baseline. We operate under ISO 9001:2015, and every batch undergoes Tensile Strength & Moisture testing in our internal lab.

Warranty Policy: If any quality issue arises (caused by manufacturing), we offer a 100% Replacement or Refund Compensation policy. We value long-term reputation over short-term profit.

A: We support flexible terms to support our partners' cash flow.

Standard: T/T 30% deposit, 70% balance before shipment (inspection photos/videos provided).

Security: We highly recommend Alibaba Trade Assurance for transaction security. For established partners, we accept L/C (Letter of Credit) to facilitate large procurement projects.

A: Yes. Our cable ties are fully certified to minimize your import risk:

Safety: UL Listed (File E534005), CE Certified.

Environment: RoHS & REACH compliant (Halogen-free).

These certificates ensure your products can legally enter major retailers like Home Depot, Walmart, or Bauhaus.