Demystifying the Higher Price of Nylon 66: Why Clients Should Understand?

In today's competitive market, it's not uncommon for clients to question the pricing of materials used in manufacturing. One such material that often raises eyebrows is Nylon 66. Despite its higher price tag compared to other plastics, Nylon 66 offers a multitude of benefits and features that justify its cost. Here's why clients should understand and appreciate the value of Nylon 66:

|

Property |

Description |

Typical Value/Range |

|

Raw Material |

Mainly composed of polymer Nylon 66 |

Polyadipamide, hexamethylenediamine |

|

Melting Point |

High melting point, approximately 255°C |

250°C - 265°C |

|

Density |

High density, approximately 1.14 g/cm³ |

1.12 g/cm³ - 1.15 g/cm³ |

|

Moisture Sensitivity |

Sensitive to moisture, affects physical properties |

≤ 0.2% |

|

Moisture Absorption |

Exhibits some moisture absorption, relatively lower compared to other nylon types |

1.5% (at 50% relative humidity) |

|

Rigidity |

High rigidity, high strength |

High |

|

Weather Resistance |

Good weather resistance, high stability to UV radiation |

Good |

|

Dry/Wet Strength |

Strength decreases under wet conditions |

Dry strength higher than wet strength |

|

Heat Resistance |

Good heat resistance, maintains stability at high temperatures |

Long-term use temperature up to 150°C |

|

Thermal Stability |

Excellent thermal stability, resistant to decomposition or degradation |

Good |

|

Friction Coefficient |

Nylon 66 has a relatively high surface friction coefficient |

0.25 - 0.35 |

|

Environmental Adaptability |

Good environmental adaptability, suitable for various environments |

Suitable for room temperature to high-temperature environments |

|

Chemical Resistance |

Exhibits resistance to certain chemicals |

Resistant to acids, alkalis, oils, and fats |

|

Processability |

Easily processed into various shapes, such as injection molding, extrusion, etc. |

Good |

|

Color Stability |

Good color stability |

Good |

|

Electrical Properties |

Possesses certain insulation properties |

Insulating material |

|

Flame Retardancy |

Can be improved with flame retardants |

V-2 rating |

|

Biocompatibility |

Exhibits some biocompatibility, suitable for some medical and food contact applications |

Suitable for medical and food contact applications |

|

Recyclability |

Can be recycled with proper processing |

Recyclable |

|

Cost |

Relatively high cost, but superior performance |

Relatively high |

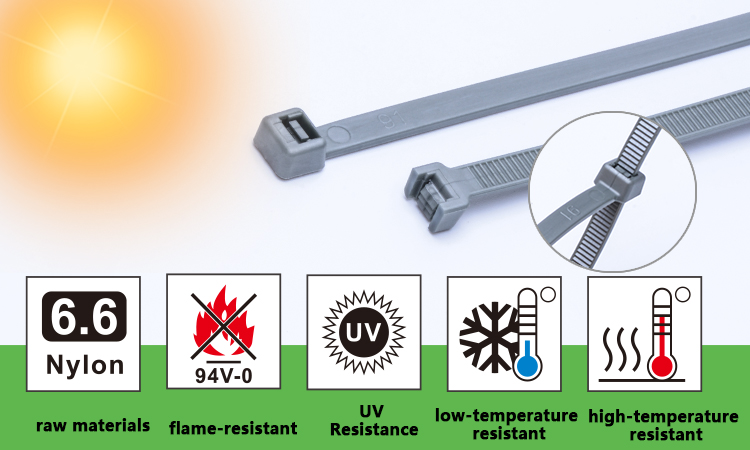

1.Superior Mechanical Properties:

Nylon 66 boasts exceptional mechanical properties, including high strength, stiffness, and toughness. Its superior resistance to wear and tear makes it an ideal choice for applications subjected to heavy loads and constant use. Clients should recognize that these properties translate into longer-lasting and more durable products, ultimately reducing maintenance costs and enhancing product reliability.

2.Excellent Thermal Performance:

Another distinguishing feature of Nylon 66 is its excellent thermal performance. With a high melting point and resistance to heat distortion, Nylon 66 can withstand elevated temperatures without compromising its structural integrity. This thermal stability makes it suitable for use in demanding environments where exposure to heat is a concern, such as automotive under-the-hood components and electrical enclosures.

3.Chemical Resistance:

Nylon 66 exhibits outstanding chemical resistance, making it resistant to oils, greases, solvents, and various chemicals. This property is particularly advantageous in industries such as automotive, aerospace, and electronics, where exposure to harsh chemicals is common. Clients should recognize that the use of Nylon 66 ensures the longevity and reliability of products in such demanding applications.

4.Versatility and Design Flexibility:

Nylon 66's versatility and design flexibility are unmatched. It can be easily molded into complex shapes and intricate geometries, allowing for the production of customized components tailored to specific requirements. Clients should understand that this flexibility enables innovative design solutions and opens up new possibilities for product development.

5.Enhanced Performance in Challenging Environments:

Whether it's exposure to extreme temperatures, moisture, or mechanical stress, Nylon 66 excels in challenging environments. Its ability to maintain performance under adverse conditions ensures the longevity and reliability of products, making it a preferred choice for critical applications where failure is not an option.

In conclusion, while the higher price of Nylon 66 may initially raise concerns among clients, it's essential to understand the value it brings to the table. From superior mechanical properties to excellent thermal performance and chemical resistance, Nylon 66 offers a host of benefits that justify its cost. By recognizing and appreciating these advantages, clients can make informed decisions that lead to the development of high-quality, reliable, and long-lasting products.