Low-temperature resistant cable ties are used in extreme low-temperature environmental conditions. The PA66 material with low temperature resistant additives is specially designed to solve the problem of low temperature (-20 ℃us to -40 ℃) and low humidity applications. Under the working low-temperature environment, the cable tie can still maintain effective performance without breaking. And without falling off.Low-temperature resistant cable ties available in bulk 1000 or 500 pieces bags or smaller 100 piece bags.

Certifications

For lower prices on bulk purchases, please contact us at

Cold-resistant cable ties are ideal for cold environments like cold chain logistics, refrigeration, outdoor cable management, and industrial applications in cold regions. They remain flexible and strong in low temperatures, ensuring reliable fastening and stability.

Nyon products

Nyon is hygroscopic, it will absorb moisture, and lose the moisture too. To ensure optimum performance, the material must maintain a 2.5% water.  packaging may keep the moisture. In order to keep the quality,it's better to remain the original packaging for Inventories. if stored impropery especally in dry or cold environment, it will lose water from cable ties, and impact the use of cable ties. Once the package is opened; please use out the cable ties as soon as possible.

packaging may keep the moisture. In order to keep the quality,it's better to remain the original packaging for Inventories. if stored impropery especally in dry or cold environment, it will lose water from cable ties, and impact the use of cable ties. Once the package is opened; please use out the cable ties as soon as possible.

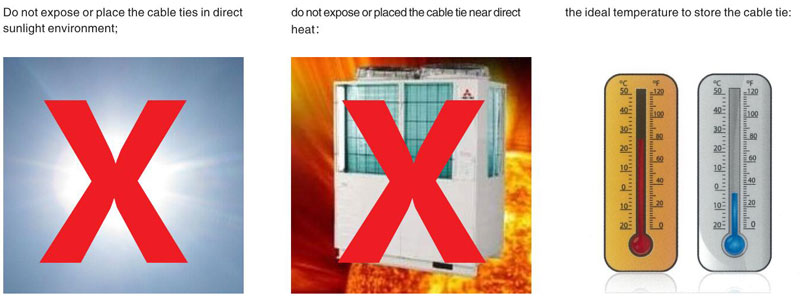

Here are our suggestion for the cable tie store:

MATERIAL: Polyamide 6.6 (low temperature resistant)

Material brand: China Huafeng158L;Radici A45L;Invista 4820L

Flammability of raw material : UL 94 - V2

Humidity absorption: 2,7%-2,8% (23°C -50% R.H.)

Installation temperature: -20°C ~+85°C. (ECR series) Installation temperature: -40°C ~+85°C.

Working temperature:-40°C ~+85°C.

Max sustaiaable tempeature for short time:+110°C.

Good resistance to bases, oils, greases, oil derivates,chloride solvents. Limited resistance to acids.

Not resistant to phenols.

Carbon black addiction gives a better UV resistance (only for Black Cabe Ties)

| Item No. | Width | Length | Max.Bundle Dia. | Min.Bundle Dia. | Min.Tensile Strength | |||||

| mm | inch | mm | inch | mm | inch | mm | inch | N | ibs | |

| TSC-100M | 2.5 | 0.098 | 100 | 3.94 | 22 | 0.87 | 2.0 | 0.079 | 80 | 18 |

| TSC-150I | 3.6 | 0.142 | 150 | 5.91 | 35 | 1.65 | 3.0 | 0.118 | 180 | 42 |

| TSC-200I | 3.6 | 0.142 | 200 | 7.87 | 50 | 2.56 | 3.0 | 0.118 | 180 | 42 |

| TSC-200ST | 4.8 | 0.189 | 200 | 7.87 | 50 | 1.97 | 3.5 | 0.138 | 222 | 50 |

| TSC-300ST | 4.8 | 0.189 | 300 | 11.81 | 70 | 3.15 | 3.5 | 0.138 | 222 | 50 |

| TSC-370ST | 4.8 | 0.189 | 370 | 14.57 | 98 | 3.86 | 3.5 | 0.138 | 222 | 50 |

| TSC-370HD | 7.6 | 0.299 | 370 | 14.57 | 98 | 3.86 | 8.5 | 0.330 | 560 | 130 |