High-temperature cable ties are used in aerospace, automotive, industrial equipment, and power plants. They provide stability and strength in extreme heat, making them ideal for cable management and fastening in high-temperature environments.

Certifications

For lower prices on bulk purchases, please contact us at

When the actual operating environment is at a high temperature, it is recommended to use cable ties containing thermal stabilizers. Thermally stable cable ties can effectively function at temperatures as high as 130 ℃, so that the tied or fixed objects remain stable. , Will not break or fall off. One-piece structure can achieve consistent performance and reliability. Cable Tie Express is equipped with thermally stable cable ties with a length of100MM--370MM( 4” –14.6”) . The heat-stable cable tie comes in two packages: 1,000 pieces in bulk bags and 100 pieces or 50 pieces in small bags.

Nyon products

Nyon is hygroscopic, it will absorb moisture, and lose the moisture too. To ensure optimum performance, the material must maintain a 2.5% water.  packaging may keep the moisture. In order to keep the quality,it's better to remain the original packaging for Inventories. if stored impropery especally in dry or cold environment, it will lose water from cable ties, and impact the use of cable ties. Once the package is opened; please use out the cable ties as soon as possible.

packaging may keep the moisture. In order to keep the quality,it's better to remain the original packaging for Inventories. if stored impropery especally in dry or cold environment, it will lose water from cable ties, and impact the use of cable ties. Once the package is opened; please use out the cable ties as soon as possible.

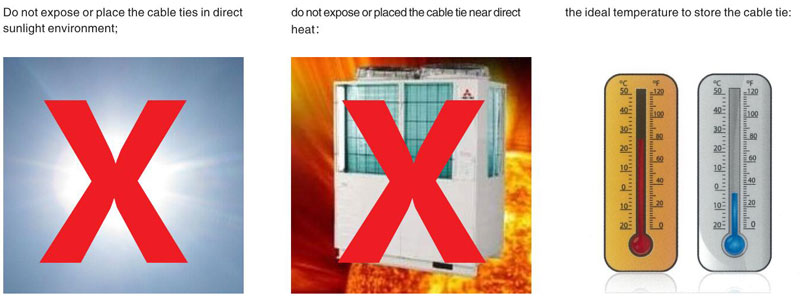

Here are our suggestion for the cable tie store:

MATERIAL: Polyamide 6.6(Heat Stabilized)

Material brand: China Huafeng158L;Radici A45L;Invista 4820L

Flammability of raw material : UL 94 - V2

Humidity absorption: 2,7%-2,8% (23°C -50% R.H.)

Installation temperature: -10°C ~+130°C.

Working temperature:-40°C ~+130°C.

Max sustaiaable tempeature for short time:+130°C.

Good resistance to bases, oils, greases, oil derivates,chloride solvents. Limited resistance to acids.

Not resistant to phenols.

Carbon black addiction gives a better UV resistance (only for Black Cabe Ties)

| Item No. | Width | Length | Max.Bundle Dia. | Min.Bundle Dia. | Min.Tensile Strength | |||||

| mm | inch | mm | inch | mm | inch | mm | inch | N | ibs | |

| TSB-100M | 2.5 | 0.098 | 100 | 3.94 | 22 | 0.87 | 2 | 0.079 | 80 | 18 |

| TSB-150I | 3.6 | 0.142 | 150 | 5.91 | 35 | 1.65 | 3 | 0.118 | 180 | 42 |

| TSB-200I | 3.6 | 0.142 | 200 | 7.87 | 50 | 2.56 | 3 | 0.118 | 180 | 42 |

| TSB-200ST | 4.8 | 0.189 | 200 | 7.87 | 50 | 1.97 | 3.5 | 0.138 | 222 | 50 |

| TSB-300ST | 4.8 | 0.189 | 300 | 11.81 | 70 | 3.15 | 3.5 | 0.138 | 222 | 50 |

| TSB-370ST | 4.8 | 0.189 | 370 | 14.57 | 98 | 3.86 | 3.5 | 0.138 | 222 | 50 |

| TSB-370HD | 7.6 | 0.299 | 370 | 14.57 | 98 | 3.86 | 8.5 | 0.33 | 560 | 130 |